Gallery

2019 Ram Promaster 1500. All of our work on this van took one month to complete

This was a facebook marketplace find that needed lots of attention to make it safe to travel in.

There were no disconnecting means to turn off the system or fuses to protect the wiring

There were even different gauge wires going to the inverter

The upper part of the bed frame was bolted to the wall of the van but the support legs were not fastened to anything so they were not doing their job very well. So we fixed that,

We wanted to be cost effective but still have a large battery bank so we installed two of the SOK 314ah lithium batteries to power the van.

We built usable storage space on top of the SOK batteries and infront of the other electrical equipment we installed.

Main fuse and On/off switch located in an easy to get to location for safety and maintenance reasons

Installed the Xantrex Freedom XC Marine 3000w Inverter/Charger. With this you are able to charge your house batteries from shore power as well as convert your 12v DC power to 120v AC power.

Built the angled shelf over the wheel well for the Victron Lynx Distributer in order to create more room on the shelf over the batteries

Re-used the Blue seas 12 spot, 12v branch circuit panel that was installed with the old electrical system in the van.

Installed the Victron Orion 12/12-30 DC-DC charger to use the vehicles alternator and charge the house batteries while the van is running.

Victron MPPT 100/50 Solar charger and disconnect. Also to the left of the solar disconnect there is a temperature sensor that controls two ventilation fans at each end of the electrical layout to keep the sytem cool

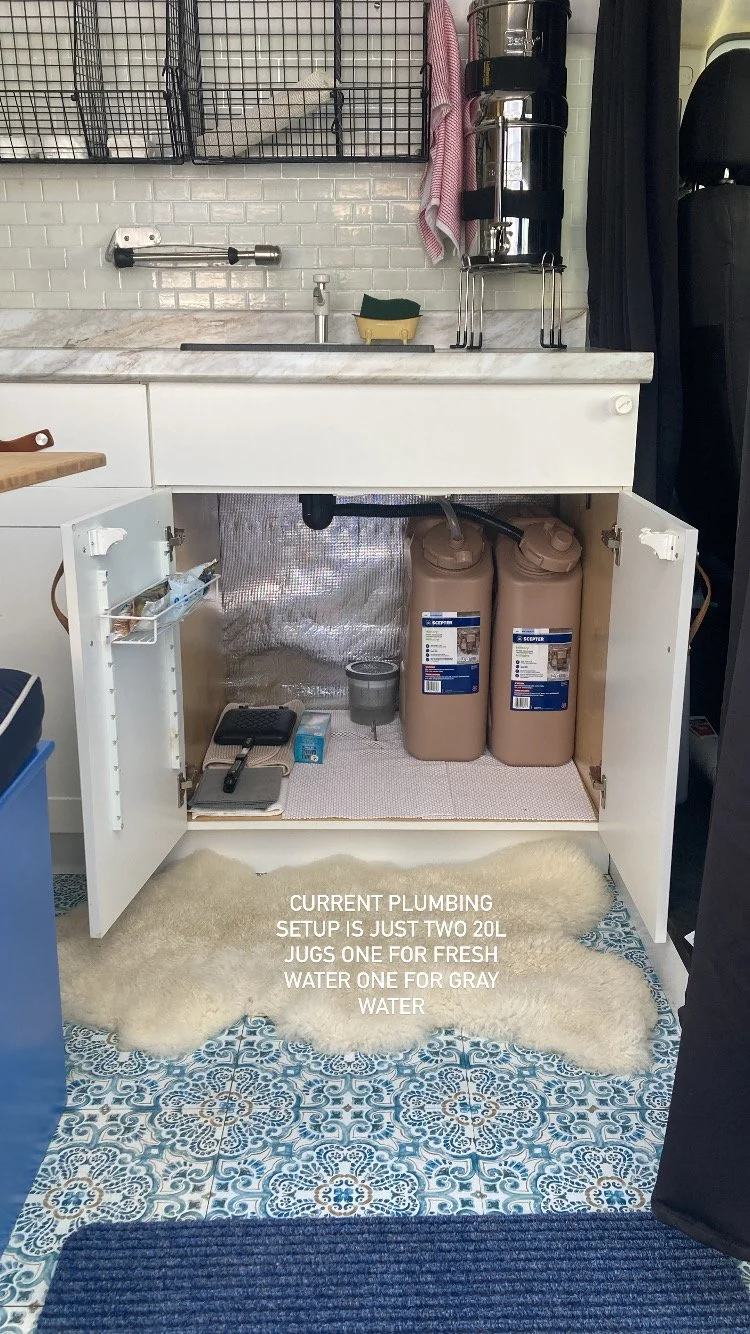

The old plumbing system worked but was not up to par for our clients standards

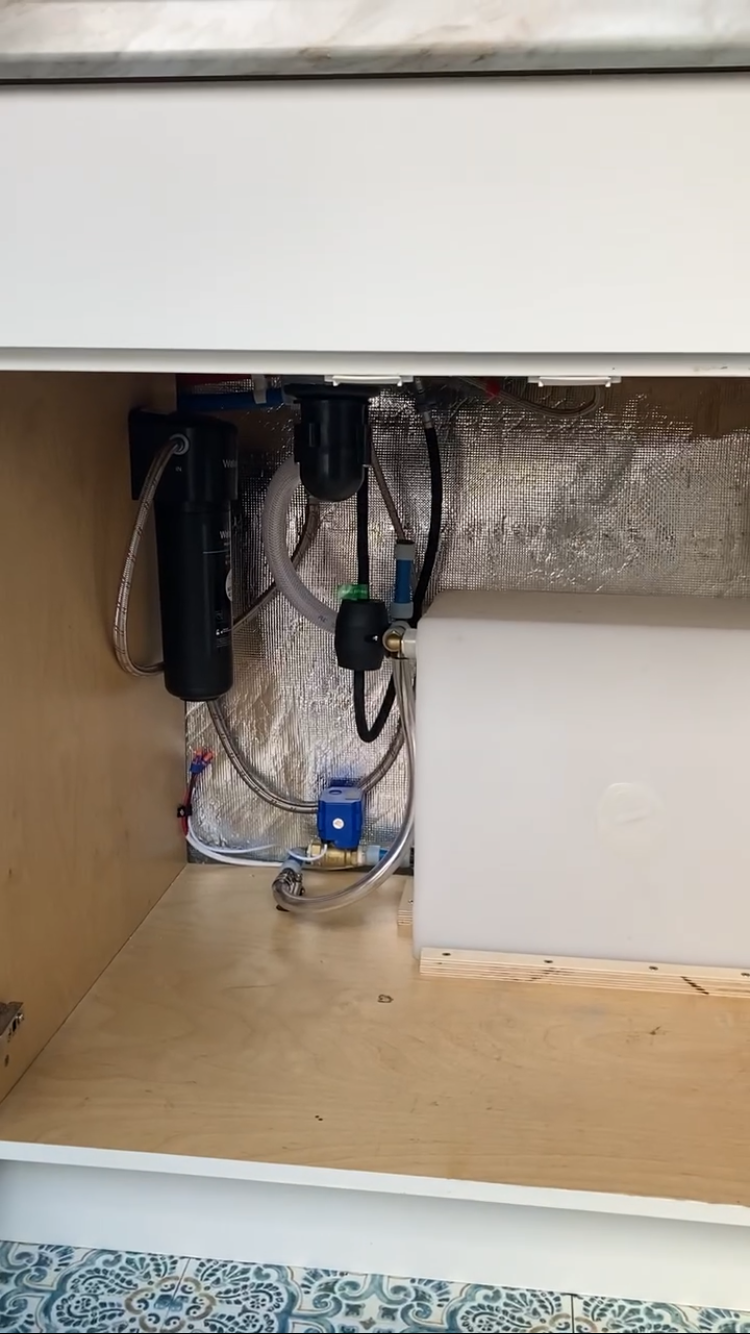

The new gray water tank is equipped with an automatic ball valve so you can empty the tank with the push of a button

Due to low ground clearance we decided to install the gray tank where the old water jugs were located.

Single stage water filter installed under the sink as well

There was a huge hole in the wall from whoever built the van originally so we made the control panel fit over the hole to make it look more finished. This Control panel houses the battery monitor, inverter controller, water pump switch and the dump valve switch

Control Panel installed

2019 Mercedes Sprinter 4x4 Winnebago Revel

Added Terrawagon Fender Armor Kit

Installed 1300lb Hedgfox Recovery winch

Fits nicely inside Flatline Van Co front bumper

When wiring a vehicle we always try to follow stock wiring harnesses for cleanliness

ARB air compressor

Air port under the hood for inflating front tires

ARB 1lb air tank installed under the passenger seat behind one of the battery boxes for the house batteries

Stainless braided lines run throughout the entire sytem

Air port mounted by trailer hitch for easy inflation for rear tires

Flatline Van Co Front Bumper

Flatline Van Co skid plate

Baja designs Squadron Pro Auxiliary

Baja Designs LP 9's (letting customer choose how they want them orientated)

MIC Tuning 12 gang switch controls the air compressor and the lights in the front bumper. Used the 12 gang to leave room for more lights in the future

LP 9's also come with the amber lens covers

The customer wanted everything wired to the MIC Tuning 12 gang Blue tooth switch

So we fabricated a mounting bracket (patent pending) that gives you a place to mount added electrical equipment in a neat way!

Between the winch, on board air compressor and new baja lights there was a lot of wiring to be done

The Stoke mounting bracket installed under the hood of the 2019 Mercedes Sprinter.

JBL speakers to replace the stock Mercedes door speakers

Added foam onto the door panel to help with door vibration at higher db

JBL badge added to the door panel

New Tweeters were also installed in the dash

Both door speakers and tweeters are wired to crossovers increase speaker efficiency by 2 db

1975 Chevy Stepvan

Worked out of the back of the shop Quigley for this build

Customer had the van painted white. It was maroon when they picked it up on market place

There was already a serving window due to it already being an ice cream truck. But we cleaned that up in order to fit in a new one

We gutted the old wiring, insulation, wall studs, and ceiling

Cut in holes for an air conditioner and a ventilation fan

Wired it for lighting, running water, multiple freezers, a fridge, air conditioning and more

Used marine grade wire and installed rubber edging where it passed over metal edges

Installed flooring

Insulated the walls and ceiling

Used FRP for the walls

Built simple economical cabinetry that is later wrapped in white 1/16" brake metal for food truck regulations

Customer wanted to use the old sink counter that was already in the van

On the driver side there is a deep freezer, a 12 hole dipping cabinet, counter top for blenders and milkshake machines. On the passenger side is the sink, counter top for working space, serving window and a fridge for ingrediants.